Location of Work: Northeastern US and University of Massachusetts – Amherst

Authors:

Relevant Sector/Industry: Academic/University

Site: https://www.umass.edu/stockbridge/umass-student-farm

Open to Collaboration: Yes

Abstract

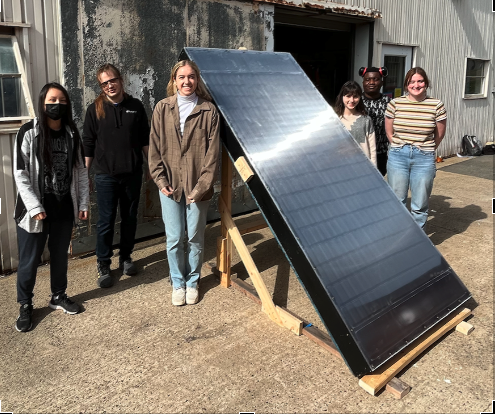

The climate crisis, defined by rapid and ongoing changes in global climates, is caused in part by the release of large amounts of greenhouse gases into the atmosphere. Organic waste has played a significant role in the climate crisis, with food production accounting for 26% of global greenhouse gas emissions [1]. Biodigesters provide a sustainable solution for managing organic waste while generating renewable energy and nutrient-rich fertilizer. Biogas, the gas produced by the anaerobic digestion of organic matter, is a sustainable, carbon-neutral energy source for cooking on gas stoves or converting to electric energy generators. However, temperature is a key limiting factor for the application of small-scale biodigesters in the Northeastern region of the US. The methanogenic bacteria responsible for breaking down organic matter and producing biogas operate optimally at temperatures between 30-40°C. Below this range, biogas production can slow down and halt. Therefore, developing a method of winterizing small-scale biodigesters for its application in the Northeast US climate would provide individual users with a renewable energy source and ecological waste management system year-round. Here, we developed a biodigester heating system by utilizing passive solar thermal technology (figure 1). A solar air heater constructed of aluminum soda can channels collect and concentrate solar thermal energy, and this energy provides heat to a biodigester through the continuous exchange of heat from air. A solar-powered fan pushes air circularly in a closed system through the solar air heater and an insulation box that houses a 32-gallon biodigester via insulated air ducts

Biodigester Size used: Small (5-20 cubic meters)

Location of Work: Northeastern US and University of Massachusetts - Amherst

Authors:

Relevant Sector/Industry: Academic/University

Site: https://umassuraad.github.io/index.html

Open to Collaboration: Yes

UMASS URAAD WebsiteAnaerobic digestion is the process of converting organic materials, mainly food waste, into gases such as methane and carbon dioxide, as well as water. This is done using many species of anaerobic bacteria in tandem, each specializing in the breakdown of certain molecules in the organic mixture, or slurry.

Conversion of organic waste to methane occurs in two phases, composed of four total steps. In the first phase, liquefaction, complex compounds such as carbohydrates and proteins are converted by bacteria into simpler fatty acids, which are more volatile and can thus be easily converted into gases. Liquefaction comprises the first two steps of anaerobic digestion: hydrolysis and acidification. In hydrolysis, large organic polymers are broken down into component molecules small enough to be processed. Acidogenesis, the second step, is where the products of hydrolysis are uptaken by acidogenic bacteria to produce volatile fatty acids. These include acetate, which is ready to be processed into methane, and larger organic acids, which must be first converted into acetate before processing.

The formation of gas is accomplished in the second phase, gasification, in which bacteria form gases (primarily methane and carbon dioxide) from the volatile organic acids formed in liquefaction. Gasification comprises the final two steps of anaerobic digestion: acetogenesis and methanogenesis. In acetogenesis, larger volatile acids are converted into acetate to allow for conversion by methanogenic organisms (archaea and bacteria) into methane. Hydrogen is also produced here. The final step, methanogenesis, sees the production of methane as well as some carbon dioxide. About 66% of methane is produced by acetoclastic methanogens using acetate, while about 33% is produced by hydrogenotrophic methanogens using hydrogen [1]. Methanogenesis using other molecules has also been observed.

A small portion of the organic matter is used by bacteria for replication, however about 90% of original matter has been observed to end up as methane [2]. Methane, in turn, can be used as a relatively clean and efficient fuel, as when burned it releases more heat and light by mass than other hydrocarbons, and produces less pollutants [3].

Feed Type used: cat, chicken, and cow

Biodigester Size used: Medium and Small (5-20 cubic meters)